Wheat Flour Production

December 8, 2025, 7:30 am

Wheat is grown in most parts of the world, from near-arctic to near-equatorial latitudes.

Wheat is unique among cereals since the total area under wheat cultivation world-wide is larger than for any other cereal and the amount of wheat traded internationally exceeds that of all other grains.

The demand for wheat far exceeds the supply which poses a threat to global food security especially in the Middle East and Africa. Wheat is a crucial ingredient in the world's food supply. Global wheat prices are on the rise as a result of the Russia and Ukraine war, both countries account for about 30 % of global world trade of wheat

NUTRITIONAL VALUE OF WHEAT

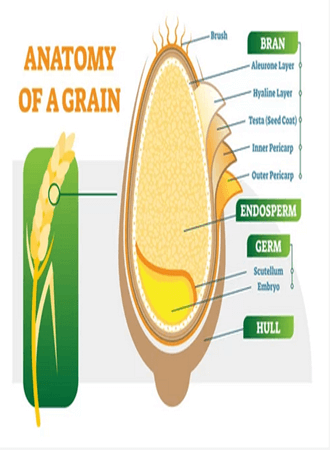

Wheat is a good source of carbohydrates (starch). Cereals generally contain small amount of lipids. Lipids are distributed all over the wheat grain in minor constituents, although more in the germ.

The endosperm contains most of the proteins of the wheat grain which are referred to as storage proteins (mainly gliadins and glutenins) and constitutes 10% to14 % of the wheat grain.

TYPES OF WHEAT

There are two types of wheat with respect to their protein (gluten) content: hard wheat and soft wheat. Hard wheat flour has high protein content while soft wheat flour contains lower quantity of protein. Hard and soft wheat flour contains 15% and 10 % proteins respectively.

Hard wheat flour is used to make bread and fine cakes because of its high protein level, whereas soft wheat flour is used to make breakfast foods, cookies and crackers.

Wheat can also be classified into five classes based on some factors (hardness, species, colour, planting time), namely soft red winter, white, hard red winter, durum and hard red spring.

White wheat may be more acceptable compared with red wheat as a result of less bitter taste of white wheat. This is particularly for whole grain products because the bran contains high levels of volatile phenolic compounds which are potentially bitter.

USES OF WHEAT

Wheat is mostly used in the form of flour. Wheat's utilization is determined by its grain composition and protein level. Whole wheat flour is very high in dietary fibre therefore could be classified as an excellent health-building food with health promoting benefits. Wheat quality is mainly judged by the quantity and the strength of the gluten content rather than nutritional quality.

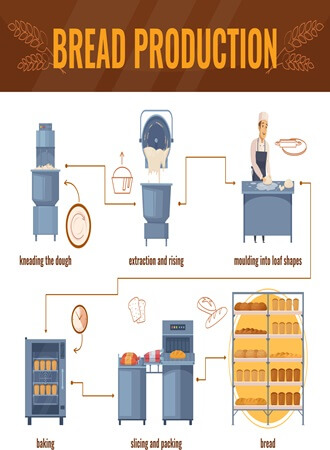

The quality of product is determined by the quality of flour, a very good example is seen in bread making. As a result of the gluten contained in wheat, it is the commonest used cereal in bread production.

Bread is the major product produced from wheat flour and it is the most consumed baked product worldwide. The major difference between wheat flour and flours from other cereals is the ability of dough formation in wheat flour.

Wheat flour is used mainly in the production of snacks such as pies, biscuits, cookies. It is also used in the production of pizza. Durum wheat is the most cultivated common wheat; it is used for pasta products such as macaroni and spaghetti.

Starch may be derived from wheat. Starch is commonly used in industries (food and non-food) and in the home. Due to its pasting property, it is used in products such as custards, gravies and soups. The starch obtained from wheat may be used in confectionery and brewing after being converted to syrup.

Due to the bonding properties of wheat starch, it may be used as adhesive in cardboard boxes. The starch may also be modified and used in paper and fabrics sizing.

Wheat is a very useful grain and beneficial in diverse ways such as both nutritionally and in confectionery. Wheat also has antioxidant properties which makes it beneficial to human health.

Wheat Flour

Wheat flour is the product prepared from the grain of common wheat, Triticum aestivum L., or club wheat, Triticum compactum Host, or mixtures thereof, by grinding or milling processes in which the bran and germ are partly removed and the remainder is comminuted to a suitable degree of fineness.

WHEAT FLOUR PRODUCTION

Wheat flour is produced by milling, a gradual reduction process involving cycles of breaking, sifting, sorting and crushing the wheat kernels. In primitive milling operations, pairs of stones were used to reduce the grain to flour or meal. This process was revolutionized when grinding by rollers came into large-scale use in the late 1800s.

The development in the 1960s of impact milling (with high-speed grinders) enabled further grinding of flour particles and the use of air classification (with swirling air tunnels) allowed the separation of flour particles that are too fine for sieving.

Wheat Flour Conversion Factors from Raw Material

Theoretically, a flour yield of 83% from wheat grain is possible but more common are yields between 72 and 77%(on a clean wheat basis). This can be increased to 90% if whole-wheat flour is produced - i.e. if only the coarsest brans are removed. Factors affecting the flour yield include the size and shape of the kernels, the thickness of the bran and wheat hardness. Soft wheats have higher flour yields.

It must be noted that wheat bran, the main by-product from milling, can also have a commercial use – mainly as animal feed – and therefore has a market value in addition to wheat.

Wheat Flour Food Standards

The following standard applies to wheat flour for direct human consumption prepared from common wheat, Triticum aestivum L., or club wheat, Triticum compactum Host., or mixtures thereof, which is prepackaged ready for sale to the consumer or destined for use in other food products.

General Quality Factors of Wheat Flour

There are 3 major qualities that wheat flour for food consumption must possess:

- Wheat flour and any added ingredients shall be safe and suitable for human consumption.

- Wheat flour shall be free from abnormal flavours, odours, and living insects.

- Wheat flour shall be free from filth (impurities of animal origin, including dead insects) in amounts which may represent hazard to human health.

Moisture Content of Wheat Flour

The acceptable moisture content of wheat flour is 15.5% m/m max. Lower moisture limits should be required for certain destinations in relation to the climate, duration of transport and storage.

Wheat Flour Treatment Agents

Treatment agents are substances used in wheat flour to enhance shelf-life, texture, flavor, and appearance by controlling microbial growth, preventing spoilage (oxidation/rancidity), stabilizing mixtures (fats/water), and improving baking properties (gluten strength, volume).

The treatment agents that can be used in wheat flour should adhere to the levels in the table below:

|

FLOUR TREATMENT AGENTS |

MAX. LEVEL IN FININSHED PRODUCT |

|

L-ascorbic acid and its sodium and potassium salts |

300 mg/kg |

|

L-cysteine hydrochloride |

90 mg/kg |

|

Sulphur dioxide (in flours for biscuit and pastry manufacture only) |

200 mg/kg |

|

Mono-calcium phosphate |

2,500 mg/kg

|

|

Lecithin |

2,000 mg/kg |

|

Chlorine in high ratio cakes |

2,500 mg/kg |

|

Chlorine dioxide for yeast raised bakery products |

30 mg/kg |

|

Benzoyl peroxide |

60 mg/kg |

|

Azodicarbonamide for leavened bread |

45 mg/kg |

WHEAT FLOUR CONTAMINANTS

In order for safe human consumption of wheat flour, the following contaminants should be maintained at these levels

Heavy Metals

Wheat flour shall be free from heavy metals in amounts which may represent a hazard to human health.

Pesticide Residues

Wheat flour shall have less than 0.11 mg/kg of pesticide residue

WHEAT FLOUR PACKAGING

Wheat flour shall be packaged in containers which will safeguard the hygienic, nutritional, technological, and organoleptic qualities of the product.

The containers, including packaging material, shall be made of substances which are safe and suitable for their intended use. They should not impart any toxic substance or undesirable odour or flavour to the product.

When wheat flour product is packaged in sacks, the sacks must be clean, sturdy and strongly sewn or sealed.

REFERENCES

FAO CODEX STANDARD 152-1985 FOR WHEAT FLOUR

FAO Submission and Evaluation of Pesticide Residues Data for the Estimation of Maximum Residue Levels in Food and Feed

Wheat Production and Food Security: Global Statistics and the Nigerian Situation – A Review by O. M. M. Nwadi and T. M. Okonkwo

Share This Article: