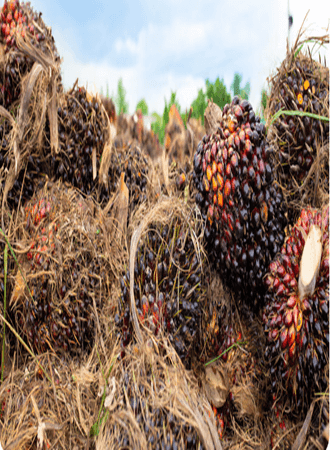

Palm Oil Farming And Processing In Nigeria

December 5, 2025, 8:32 am

Nigeria was the largest producer of palm oil globally in the ‘60s, exporting an average of 150,000MT per year.

The downfall of the Nigerian palm oil industry can be traced to factors such as the negative effects of the Nigerian civil war which took place between 1967 and 1970, lack of investment in palm oil extraction technology and a lack of technical competence and training.

Palm oil remains the cheapest and most edible vegetable oil globally. The oil palm tree produces 4.95 tons of edible oil per hectare (ha), six times more than the rapeseed tree, the next highest. Data from the United States Department of Agriculture (USDA) show that India, Indonesia, the European Union (EU), China and Pakistan are the top five consumers of palm oil globally. Combined, they account for approximately 51% of global consumption. Egypt and Nigeria are the largest consumers in Africa.

Uses of Palm Oil

90% of palm oil is consumed by the food industry and the remaining 10% is used by the non-food industry. For example, the Noodle industry in Nigeria alone consumes over 70,000 MT of imported palm oil due to the inadequacy of domestic production. Frustrated by unavailability of sufficient oil palm in the Nigerian market, some noodle-makers have proactively implemented strategic alliances to invest in oil palm plantations.

The table below shows the different uses of palm oil

|

Several Users of Palm Oil Products

|

|

|

Food Usage Cooking oil Deep frying oils Margines Shortenings Spreads Alternative fats Confectionary fats Ice creams Nutrition Others |

Non-Food Usage Cosmetics Detergents Soaps Drugs Candles Lubricating oils Grease Surfactants Chemicals Agric uses Paints Coatings Electronics Biodiesel Leather |

Palm Oil Demand in Nigeria

There’s a demand of over 400,000 MT of palm oil in Nigeria due to insufficient local production. Analysts estimate that the major importers of crude palm oil (CPO) in Africa, Nigeria and Benin Republic, imports 450,000MT and 280,000MT of palm oil per annum, respectively.

Sources claim that most of Benin Republic’s CPO imports find their way into Nigeria as Benin exports close to 265,000 MT of palm oil annually. Thus, actual shortage of CPO in Nigeria could be as high as 600,000 MT if the exports from Benin Republic are taken into consideration.

The technical palm oil (TPO) produced locally is preferred because of its “tangy” flavor, a feature which is missing in imported palm oil. On the other hand, the demand for special palm oil (SPO) has been on the increase, which is further refined and bleached, to cater to the needs of industrial processors. There is an estimated shortage of over 250,000 MT of TPO and 200,000 MT of SPO which is fulfilled through imports.

PALM OIL PRODUCTION IN NIGERIA

The palm oil production belt in Nigeria includes the states of Abia, Anambra, Bayelsa, Akwa-Ibom, Cross River, Delta, Eboniyi, Ekiti, Enugu, Ondo, Ogun, Osun, Oyo, Imo and Rivers.

The total land that is ideal for oil palm plantation totals approximately 24 million hectares in the whole of Nigeria. However, little over 3.0 million hectares of land is put to use. The total plantation area of oil palm in and around Niger Delta ranges from 1.4 million hectares - 1.8 million hectares, the wild grove plantation is more than 1.1 million hectares, smaller plantations approximates to 26,000 hectares and organized large estates adds up to another 100,000 hectares

Challenges of Palm Oil Farming in Nigeria

One of the biggest challenges faced by Nigeria’s oil palm industry is the dispersed nature of the oil palm plantations. Most of these plantations, as much as 80.0%, are small holdings of marginal farmers, which fail to enjoy economies of scale attributable to large scale farming. The farmers, due to limited funds do not have access to improved seedlings, and technologically advanced methods of processing. The existing land management regulations adds to the woes of oil palm industry as the crop takes long gestation periods to yield returns.

Palm Oil Farming in Nigeria

Palm oil production starts with the trees that are producing fruit, the harvesting of the fruit, and then the processing of the fruit. Nigeria has two main palm production systems, the wild grove and the planted farms, with the wild grove producing about 80% of total fruit for processing. The varieties under production are a critical function of the long term productivity and competitiveness of Nigerian palm oil industry.

Three varieties of Oil palm are available in Nigeria: Dura, Pisifera and Tenera. The preferred variety among palm oil farmers in Nigeria is the highbreed Tenera which is a crossbreed of the Dura (female) and the Pisifera (male).

The Characteristics of the Three Fruit Varieties for palm oil farming are shown below:

|

DURA

|

PISIFERA

|

TENERA

|

|

Thick-shell

|

Shell-less

|

Thin-shell

|

|

Thin-mesocarp

|

Mainly monocarp

|

Thick mesocarp

|

|

Viable embryo

|

Unviable embryo if present seed sterile

|

Viable embryo

|

|

Large kernel

|

Very small kernel and sometimes no kernel in most fruits

|

Good size kernel

|

|

Contains very small quality of oil

|

The oil content of the fruit is the highest among the three fruit forms

|

|

|

Unimproved

|

Unimproved

|

Improved

|

In terms of comparison, the fruit of the Tenera variety contains 25% oil, by weight, and the Dura variety 18%, so the same amount of Tenera can yield 30% more oil than the equivalent fruit of the Dura.

Palm Oil Farming Systems in Nigeria

The methods of palm oil production in Nigeria falls into one of three systems. These systems are:

- Wild groves.

- Small and medium holder plantations with many of the small holder systems intercropped with food crops and sometimes other cash crops

- Estate plantations

Wild Groves

These are vast lands with naturally-occurring palm trees that have been planted for generations. Owners of these land lease out the trees to individuals to harvest the fruits. There is no investment by the owners and the palm oil variety is typically Dura. The average yield is estimated at 1.5FFB (fresh fruit bunch) tons/ha/year.

Small and Medium Plantations

This system comprises of palm trees in sizes of land that ranges from 1 hectare to 100 hectares. This category of palm oil production is further divided into 3 categories based on the size of the land

- Small Scale Farmers: Owners of 1-10 ha of planted palm and mostly Tenera variety. Some are inherited and some are new. The use of manual labor and proper spacing of plants are common practice with this group. Generally most of the small holder farms in this category are poorly maintained in terms of weeding, slashing, fertilizer application. Hence, inappropriate fertilizer or chemicals are common in this structure. The average yield is 3FFB tons/ha/year.

- Medium Scale Farmers: Owners of 10 and 25 ha using manual production technology. The average yield is also 3 tons FFB/ha/year.

- Large Scale Farmers: Owners of 25 and 100 ha with adoption of small mechanization and herbicides application. The average yield is 5 tons FFB/ha/year.

Estates Plantations

This palm oil production system is made up of palm trees on land that is a minimum of 100 hectares in size. They are further divided into three categories, according to land size:

- Small Estates: The area under cultivation per holding in this group is between 100 and 1000 hectare (ha) and owned by individuals and cooperatives. There is a reasonable level of mechanization but timely application of fertilizer remains a challenge owing to availability. The average yield is 5 tons FFB/ha/year.

- Medium Estates: The area under cultivation in this group is between 1,000 and 5,000 hectare (ha) per holding. These are owned by corporations or State governments and most of the corporations are linked to a medium sized mill. The average yield is 5 tons FFB/ha/year.

- Large Estates: The area under cultivation per holding is greater than 5,000 hectare and some are integrated into large scale processing. The average yield is 5 tons FFB/ha/year.

Palm Oil Farming Inputs

The Palm Oil value chain inputs comprise of sprouted seeds and seedlings, fertilizer, herbicides and insecticides (chemicals). However, the availability, affordability, skillful and proper combination of these inputs determine, to a large extent, the productivity of the oil palm plantations

The role and importance of each of these inputs are explained below:

Seedlings

The recommended new variety is Tenera, and NIFOR (Nigerian Institute for Oil Palm Research) is the main supplier of this variety to nurseries and large estates for production. One of the main concerns has been that farmers are not certain that they are actually getting the variety of palm tree that they are purchasing.

The market for sprouted seeds/seedlings is characterized by many buyers and very few suppliers. The buyers range from the very smallholder farmers to very large estate-holder farmers. While NIFOR is the main suppliers of sprouted seeds/seedlings, other sources of sprouted seeds/seedlings are the large scale oil palm companies

Fertilizer

Fertilizer is another major input in the palm oil value chain. Different types of fertilizers are required at different stages of growth for palm trees. Productivity declines without the appropriate application of fertilizers to the palm tree. However, farmers at all levels (except the best functioning large estates) have difficulty accessing the fertilizer (a combination of availability and the cash to purchase it).

The number of bags of fertilizer which a farmer buys in a year depends on the ages of the palm trees and the size of the holdings. In most cases, 2 and 3 bags of fertilizer are applied per hectare. The activities of contractors and middle men involved in the distribution of fertilizer to farmers add to the frustrations experienced by farmers.

Chemicals (herbicides, insecticides, etc)

Herbicides are used to combat weeds in the plantation, while insecticides are used to control insects. However, less than 5% of palm oil farmers in Nigeria apply insecticides in their farm.

Poor quality of herbicides is a constraint, considering the influx of adulterated herbicides in the market. A good number of farmers have lost money and endangered their farms due to the use of fake or adulterated herbicides which could only be detected after application. Owing to poor quality of herbicides, most farmers prefer inter-cropping as a strategy for combating weeds in the farm.

Palm Oil Processing

Oil extraction from palm fruits is a complex process. The variety of technologies in use varies by production system.

- In the traditional TPO markets, most of the palm oil is produced by women using the rudimentary mortar and pestle mentioned above. These achieve rates of extraction of about 25% of the available oil in the fruit, so there is lots of lost yield.

- More advanced small farmers have started their own processing using mini-improved processing units. These semi-mechanized integrated small-scale processing equipment (SSPE), have been improved considerably since their initial introduction. They will use a digester, press, and a small engine.

- Medium scale processors are able to process about 0.5 tons FFB/hour, and the equipment has screening machine, boiler, digesters, press, clarifier, and generator. These are able to produce SPO, and employ about 10 personnel to operate. They require a good source of water and can generate a 13-14% yield of oil (equivalent to 50-70% of available oil).

- Large scale processors can handle more than 1 ton of FFB/hour (attached to estates with large mills) may process up to 60 tons of fruit/hour, with yields of 15-18% of oil from the fruit (equivalent to 75% of available oil in the tenera variety).

Regardless of the technology used, oil extraction from palm fruit follows the same basic nine steps listed below:

1. Steam sterilization of bunches (inactivates lipase enzymes and kills microorganisms that produce free fatty acids, reducing oil quality).

2. Stripping fruit from bunches.

3. Crushing, digestion, and heating of the fruit.

4. Oil extraction from macerated fruit (hydraulic pressing).

5. Palm oil clarification.

6. Separating fiber from the endocarp.

7. Drying, grading, and cracking of the endocarp.

8. Separating the endocarp from the kernel.

9. Kernel drying and packing.

The product of step 5 is termed crude palm oil (CPO), which can be either TPO or SPO. In order to produce the more advanced products like RBDO (Refined Bleached Deodorized Oil), it must be refined to remove pigments, free fatty acids, and phospholipids.

If you would like to see how to start a profitable palm oil farming and processing business in Nigeria producing TPO (technical palm oil) and other products, you can purchase our Palm Oil Farming & Processing business plan.

Our Palm Oil Farming & Processing business plan will show you the costs and financial analysis of starting an estate palm oil plantation with efficient processing and production of palm oil products. You will get the detailed breakdown of palm oil farming inputs, palm oil processing equipment needed and 5-years’ financial analysis of operating a successful palm oil farming and processing business.

For a payment of N300, 000, you can purchase our Palm Oil Farming & Processing business plan. If you prefer to make your payment offline, call/chat with us at +2348089864121 or send an email: agsolutions@agricdemy.com

REFERENCES

Palm Oil Value Chain Analysis in the Niger Delta by Foundation for Partnership Initiatives in the Niger Delta (PIND)

Nigeria Oil Palm Industry Report by Business Day Intelligence

United States Department of Agriculture (USDA)

Share This Article: