Tomato Paste Production in Nigeria

December 19, 2024, 7:23 pm

The tomato industry is a multibillion-dollar global enterprise. Worldwide tomato production is currently over 38.54 million metric tons (MT), with an export value of more than $5 billion dollars.

Tomato Paste Production in Nigeria

Nigeria is the 2nd largest producer of tomatoes in Africa, at 2.3 million MT per year, wastes 45% of its produced tomatoes due to the short shelf life of tomatoes and the existing supply chain causing food insecurity.

Nigeria imports over 400,000 metric tons of processed tomato paste estimated at over 350 million US dollars annually through its sea ports. The tomato industry in Nigeria is currently skewed toward the importation of tomato paste in cans, rather than the manufacturing of fresh tomatoes. Farmers, on the other hand, sell large amounts of fresh tomatoes in the markets, despite the fact that they suffer significant post-harvest losses due to a lack of preservation facilities.

The presence of such a surplus is critical for Nigeria’s potential production of a tomato processing industry. Processing of highly perishable, non-storable crops like tomatoes is usually promoted for two reasons: to absorb excess supply, particularly during gluts caused by primarily rain-fed cultivation; and to add value to the value chain through a value-added method.

Benefits of Tomato Farming

Tomatoes are one of Nigeria’s most popular vegetable crops. After potato and sweet potato, it is the world's largest vegetable crop, but it tops the list of canned vegetables. After onions and pepper, tomato is the most essential vegetable in Nigeria. It is a staple of most people’s diets and a low-cost source of vitamins. It also contains a significant amount of water, calcium, and niacin, all of which are important for man's metabolic activities. Tomatoes are high in vitamins A, C, and E, as well as minerals that are beneficial to the body and protect it from disease.

Tomato Paste Production

To keep the post-harvest losses of tomatoes to a minimum, it is important to know how tomato paste is produced. Tomato paste gives tomato a longer shelf-live and allows tomato producers to make more money from their efforts.

Tomato paste production process involves the following steps:

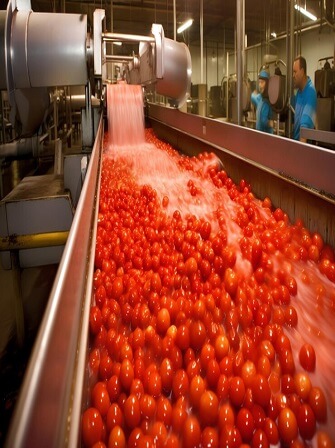

Washing

Fresh tomatoes arriving at the plant in trucks are unloaded into a collection channel (also known as flume), a stainless steel or cement duct into which a quantity of water 3 to 5 times higher than the amount of unloaded tomato is continuously pumped. For example, a 10 tons/hour rate requires at least 30 m3/hour of water.

Sorting

This water flow carries the tomatoes onto the roller elevator, which then conveys them to the grading station. Delivery trucks park-up alongside the flume and, while the trailers containing the tomatoes are being tilted towards it, an operator, using a special tube, pipes a vast quantity of water inside the truck, so that the tomatoes can flow out from the special 50 x 50cm opening. In this way the tomatoes and the water will be gradually fed into the flume without getting damaged.

The tomatoes then arrive at the grading station, after having been rinsed under a clean water spraying system (preferably drinking water). Here, staff removes the green, damaged and excessively small tomatoes which are placed on a reject conveyor (or an auger) and then collected in a large box or directly inside a truck to be taken away.

Chopping/ Crushing

The tomatoes suitable for processing are transported to the chopping station (a hammer mill or a special mono-pump provided with pre-feeding screw) where they are chopped (broken and pulped).

Pre-Heating

The pulp is pre-heated to 65-75 °C for Cold Break processing or to 85-98 °C for Hot Break processing. The main control panel on the evaporator regulates the pre-heating temperature.

Pulping & Refining

The heated tomato pulp (fiber, juice, skin and seeds) is then conveyed via a special pump to an extraction unit composed of two operating stations, pulper and a refiner, equipped with two sieves having different sized meshes. The first sieve processes solid pieces up to 1 mm, while the refiner processes solid pieces up to 0.6 mm, depending on the type of sieve fitted on the machine (the manufacturer can supply sieves with different sized holes if necessary).

Two products come out of the extraction unit: refined juice for concentration and waste for disposal. The average extractor yield varies according to different factors: the pulp’s temperature (a higher temperature will mean an increased juice yield), the variety of tomatoes treated, the type of sieve fitted, the rotation speed and the shape of the rotor on each de-juicing body unit. On average, however, the yield is about 95%. For example, if the extractor is fed with 100 kg of hot pulp, it will produce 95 kg of juice and 5 kg of waste. In addition, there is also a hypothetical product waste of about 1-3% from the grading stations.

Therefore, 100 kg of tomatoes unloaded from the trucks will produce about 93-94 kg of juice to be concentrated. At this point the refined juice is collected in a large tank with an agitator which constantly feeds the evaporator. This tank is equipped with maximum and minimum level indicators-adjusters which control the pump supplying juice to the evaporator.

Evaporation/Concentration

The juice in this storage tank is fed to the evaporator which automatically regulates juice intake and finished concentrate output; the operator only has to set the Brix value on the evaporator’s control panel; during normal working conditions, the evaporator does not require any further regulations.

The juice inside the evaporator passes through different stages where its concentration level will gradually increase until the required density is obtained in the final stage or “finisher”. Here the tomato paste is automatically extracted via a pump controlled by an electronic refractometer.

The entire concentration process (evaporation) takes place under vacuum conditions and at low temperatures, significantly below 100 °C. Product circulation inside the various concentric tubular exchangers is carried out by special stainless steel pumps which are designed to ensure that the product is conveyed inside the exchanger tubes at a speed of over 1.2 m/sec to avoid “flash evaporation” thus avoiding to get burnt. This means it is possible to process for extensive periods without having to shut down the machine.

Evaporator output is measured in liters of evaporated water per hour while concentrating tomato juice with an initial 5° Brix concentration and producing tomato paste double concentrate at 30° Brix. All the tomato juice evaporators are designed according to these parameters. The evaporative capacity of tomato juice concentrators is greatly influenced by the viscosity level. If the tomato paste has a low Bostwick value, then the concentrator’s output level will also be low; on the other hand, a higher Bostwick value means an increased output level. It is therefore fundamental to know if the productivity data supplied by a manufacturer refers to HB or CB finished products

Aseptic Filing & Packaging

The concentrate is sent from the evaporator directly inside the aseptic system tank. From here it is pumped at high pressure inside the aseptic sterilizer-cooler and then to the aseptic filler, where it is filled into pre-sterilized aseptic bags housed in metal drums. The sterilization temperature and the holding time vary according to the product’s PH value. Generally speaking, a product with a pH value equal to or less than 4.2 could have a sterilization temperature of 115 °C measured at the end of the holding section, and a holding time of at least 60-90 seconds. On the other hand, if the pH value is greater than 4.2, it is advisable to acidify the product in order to bring it to about 4.1, improving taste and final product quality.

The sterilized tomato paste is cooled down to about 35-38 °C before being piped into pre-sterilized aluminum bags housed in special metal or plastic bins via a special aseptic filler. The packaged concentrate can be kept up to 24 months depending on its pH value and ambient conditions.

Storing

When storing for over 12 months, it is however advisable to conserve it in refrigerated cells, more to reduce oxidization, which could cause darkening than to protect the product’s aseptic quality.

If you are a tomato farmer, whether in open field or greenhouse, the steps above will guide you on how to add value to your tomatoes, reduce post-harvest losses and generate more money for your tomato farming or production operations

Share This Article: