Greenhouse Irrigation Systems

October 1, 2023, 2:28 pm

Greenhouse crops are irrigated by means of applying water to the media surface through drip tubes or tapes, by hand using a hose, overhead sprinklers and booms or by applying water through the bottom of the container through sub-irrigation, or by using a combination of these delivery systems.

Greenhouse Irrigation Systems

Overhead sprinklers and hand watering have a tendency to "waste" water and also wet the foliage, which increases the potential for diseases and injury. Drip and sub-irrigation systems are the most efficient and provide greater control over the amount of water applied. Also, since the foliage does not become wet there is a reduced potential for diseases and injury.

Greenhouse Irrigation Systems

Irrigation in greenhouses can be broken into the following systems and items:

Drip Irrigation

Drip irrigation can be a valuable tool for accurate growing medium moisture control. It also saves water and labour, and reduces the potential for groundwater pollution. Drip irrigation systems eliminate runoff of water missing the pot during overhead irrigation and the volume of water applied to the pot can be controlled. In theory it should be possible to greatly reduce or eliminate leaching from pots by simply turning the system off as container capacity is reached.

Controlling drip irrigation systems with the use of a tensiometer placed in the growing medium to sense moisture tension (level) and a small computer programmed to turn the system on or off when preset moisture tensions are reached has been shown to reduce runoff from potted chrysanthemums and poinsettias to nearly zero. Vegetable crops when grown in ground beds, bags or pots are commonly watered with drip tapes. Tubing is placed atop the ground or container or woven through the bags.

Water Trays and Saucers

In this system, water is applied to the surface and is collected under the container through collection trays or saucers Water trays and saucers, depending on their shape and spacing on the bench, can greatly reduce runoff and leaching by containing the water draining from pots and holding the water which misses the pot during overhead watering.

They are inexpensive and reusable. Water which collects in them should be given adequate time to evaporate or be absorbed by the plant before further irrigation. Avoid tight plant spacing and poor ventilation to prevent disease problems when using this technique.

Sub-irrigation

Sub-irrigation systems, also known as zero runoff, are an environmentally responsibly alternative that conserves water and fertilizers. They are being installed by greenhouse growers to improve product quality, achieve more uniform growth and increase production efficiency.

In sub-irrigation systems, water and nutrient solution provided at the base of the container rises by capillary action through holes in the bottom and is absorbed by the growing media. These systems are adaptable to crops grown in pots or flats.

Advantages of sub-irrigation systems

- Water and nutrient solutions are contained and recycled

- Water and fertilizer usage decreases at least 50% over conventional systems

- Uniform watering of all containers

- Pot size and placement can be easily changed

- More vigorous plant growth

- Foliage remains dry

- Labor input is reduced

Examples of Sub-irrigation Systems

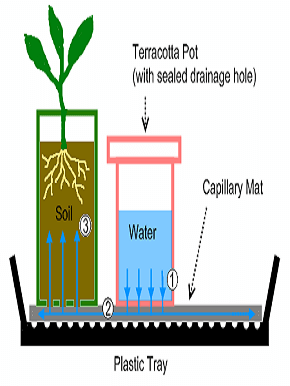

Capillary mat systems

In a capillary mat system the pots are set on a mat that is kept constantly wet with a nutrient solution. Several styles of fabric mats are available from 0.25 inches to 0.5 inches thick. The pots take up the solution through holes in the bottom. The mat is places on a level bench over a layer of plastic.

Water is supplied from drip tubes laid on top of the fabric. To keep algae under control, a layer of perforated film plastic is sometimes placed over the top of the mat. Algicides are also used. Some growers turn the mat over when a new crop is started. Containers holding nutrient solution and piping should be enclosed in black plastic or painted black to eliminate light and algae formation.

Trough system

In this system, plastic or metal troughs are placed on existing benches or supported overhead from the greenhouse structure. The troughs are installed at a slight slope (7 centimetres to 15 centimetres per 30 meters) from one end to the other. Pots are spaced along the trough. Nutrient solution, supplied from spaghetti tubes, is pumped to the high end, flows past the base of the pots and is collected in a cross gutter at the low end. The solution returns to a storage tank under the benches or below ground to be recycled.

One advantage to this system over other ebb and flow systems is the air circulation that occurs between the troughs. Another is the ability to space the troughs for different size pots. Trough systems tend to be less expensive than bench systems and can be easily installed in existing greenhouses.

Ebb and flood benches and movable trays

This system uses 4 feet to 6 feet wide watertight benches or water-tight movable trays to contain the nutrient solution. The benches, usually of plastic or fiberglass construction are installed perfectly level to maintain a uniform depth of liquid.

They can be installed as either fixed or movable depending on the crops to be grown. Channels in the bottom of the bench allow the water to distribute evenly and to drain rapidly when the water supply is shut off.

This allows the bench top to dry reducing algae growth and disease potential. In operation nutrient solution is pumped from a holding tank to a level of 0.75 inches to 1inches depth in the bench and held there for 10 minutes or long enough for the media in the container to absorb the solution. A valve is then opened and the liquid is quickly drained by gravity back into the tank. Low cost PVC pipe is used as it is not affected by the fertilizer in the water.

A filter removes any solid matter. The holding tank, usually located in the floor below the benches should have a capacity for about 0.5 gallon/sq ft of bench area. The nutrient solution is used over again but adjustments in pH and soluble salts may have to be made as water is added. Water treatment with chlorine, ultra violet (UV) light or ozone is used by some growers to prevent diseases. Control of the nutrients and flow can be manual or with a controller. Watering may be once or twice a week to several times a day depending on the weather and the size of the crop.

Flood Floors

Flooded floors work on the same principle and with the same equipment as ebb and flow benches. A watertight concrete is necessary for the floor surface and it must be installed as smooth as possible to avoid pockets. A laser transit is used to get a perfect slope, usually 0.25 inches in 10 feet. A concrete contractor having experience with flood floor system should be hired. Berms may be installed at the post line in gutter connected houses to create zones.

PVC pipe with slots or holes is usually installed in the floor in the center of the bay to supply and remove the nutrient solution as quickly as possible. Large holding tanks are necessary, usually made of concrete and lined with plastic or coated with an epoxy paint. Typically a 21 feet x 200 feet bay will require 7000 to 11,000 liters of solution. In larger greenhouses, the tank has to be large enough to hold the liquid from several bays that are operated as a single zone. New flood floors can register high alkalinity as bicarbonates in the floor dissolve.

PVC piping is used to transport the nutrient solution as it is inert to fertilizers. Monitoring of the nutrient solution is done by a computer. Fertilizer is added, usually as individual elements, to maintain the desired nutrient level. Best results are obtained if a floor heating system is installed.

This provides uniform heat in the root zone area and quickly dries the floor after the solution is drained to reduce algae formation and lower disease potential. A horizontal air flow (HAF) circulation system will reduce moisture in the plant foliage. To save handling labour, a fork lift transport and spacing machine could be used.

If you would like to start greenhouse farming in Nigeria and you need a greenhouse farming business plan or consultation service, please send a mail to agsolutions@agricdemy.com

With our greenhouse farming business plan, you will learn:

- The different greenhouse sizes available and the materials required to build them

- The different fruits and vegetables you can grow in the greenhouse and their yields

- The cost of building and constructing a greenhouse based on the size you want

- Profit and loss estimates for the first three years of running one unit of greenhouse

- Vegetable and fruit market analysis in Nigeria

- Marketing and sales strategy for running a successful greenhouse in Nigeria

- Personnel required to operate your greenhouse, key milestones and so much more!

For a payment of N50,000 you can get our greenhouse farming business plan. To get payment details, send a mail to agsolutions@agricdemy.com

If you want to learn more about greenhouse farming, check out these articles in our Greenhouse Farming section and watch our Greenhouse Farming video tutorials.

Share This Article: