Canning Catfish Techniques

July 25, 2022, 9:05 am

Canning catish process involves the heat treatment of catfish in sealed containers made of tin plates, aluminium cans or glass, until the product has been fully sterilized.

The preservative effects of canning, and the heat treatment destroys all heat sensitive bacteria and spores, inactivate the enzymes (i.e. almost stop autolysis) for prolonged shelf-life.

Canning Catfish Techniques

Canning catfish does not improve the taste or quality of catfish, but keeps the quality of catfish. Canning catfish is a value-addition to catfish farming that increase the income that farmers and entrepreneurs earn from their catfish farming business.

STAGES IN CANNING CATFISH

1. CATFISH HANDLING

Catfish Handling Methods

This process deals with activities done after the catfish have been harvested. Among the good handling practices is ensuring harvested live catfish are not allowed to struggle and die of asphyxia. Struggling after harvest hastens postmortem activity by accelerating chemical reaction rates and thereby encourage bacterial attack and possible spoilage. Catfish, unlike other species, because of its adaptive characteristics, should not be demobilized by stunning with sharp objects.

Importance of Proper Catfish Handling

Catfish begins to spoil immediately after harvest. Contamination by either spoilage or pathological bacteria is inevitable when the catfish is mishandled. Hygienic handling of catfish with best practices reduces the rate of spoilage and keep intact the quality of the catfish. Deteriorated or spoiled catfish cannot be improved in quality or nutritionally even when preserved.

Preservation only keep the quality over a length of time and not to improve quality. Therefore, handling and preserving catfish keep quality of catfish, improve shelf-life and economic returns of the entrepreneur.

2. CATFISH PRE-TREATMENT

Chef Glen Koons says that the major cause of catfish spoilage is germs. Hence after proper handling of the catfish, contamination with dirt should therefore be avoided.

Harvested catfish must be gutted with empty belly cavity left. Gutting is the process of opening up the catfish with a sharp instrument from neck to vent and removing the viscera and internal organs completely. This process removes bacteria and digestive juices which accelerate autolysis and putrification. After gutting, the catfish is cut into small parts.

3. CATFISH PRE-PROCESSING

Next the catfish parts have to be thoroughly washed with clean chlorinated and chilled water to remove bacterial slime, blood and debris. Also, washing of the belly cavity, skin and gills is important. The offal could be discarded or saved for further processing into catfish meal and catfish silage.

4. FILLING THE CANS

The cans that are to be used for storing the catfish is then filled with holding liquid. The holding liquid can be special food-grade oil marinated with garlic, vinegar, lime, clove and herbs. Distilled water mixed with lime and herbs can also be used as the holding liquid in the can. After filling the cans with oil or water, the catfish pieces are then put inside the can

5. SEALING THE CANS

When all the catfish and oil (or distilled water) have been put into the can, it is then hermetically sealed. This ensures that no air can get inside the can nor any foreign object.

6. PASTERURIZATION OR COMMERCIAL STERILIZATION

Pasteurization is a process in which packaged and non-packaged foods (such as milk and fruit juices) are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life. The process is intended to destroy or deactivate organisms and enzymes that contribute to spoilage or risk of disease, including vegetative bacteria, but not bacterial spores.

The process was named after the French microbiologist, Louis Pasteur, whose research in the 1860s demonstrated that thermal processing would deactivate unwanted microorganisms in wine.

Hence the sealed catfish cans are then heated in a special oven or kiln to effectively kill any pathogens contained inside.

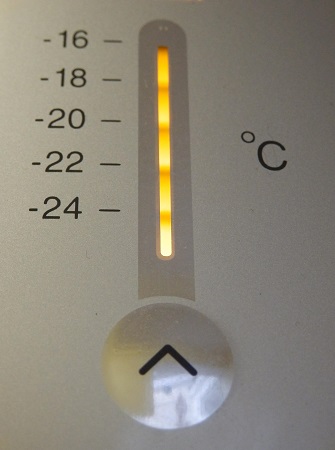

7. COOLING TO AMBIENT TEMPERATURE

The objective of chilling is to cool the canned catfish to as low a temperature as possible usually around 0°C without freezing. Chilling is an extremely effective way of preserving catfish. The enzymes action as well as growth multiplication of bacteria are drastically reduced thereby reducing the rate of spoilage.

Chilling does not prevent spoilage. To achieve maximum benefit, the catfish are to be chilled as fast as possible. The cooling rate (R) is inversely proportional to the thickness (x) of catfish:

R α 1/x

Generally, it has been found that some species have longer shelf-lives than others in ice. Fresh water catfish, tropical catfish and lean catfish have longer shelf-lives than marine, temperate and fatty catfish respectively.

The manner in which heat is taken from catfish during chilling can be described in 3 stages:

Stage 1: The temperature of the catfish flesh falls rapidly from ambient to just below 0°C

Stage 2: This stage is referred to as thermal arrest period (TAP). At TAP stage, the temperature remains stationary at 0°C to 1°C until 75% of the water in the catfish turns ice.

Stage 3: As the frozen flesh is further cold, the temperature begins to fall sharply. At this stage most of the remaining water gets frozen. Approximately 10% of water still remains unfrozen at the end of the freezing period even at -30°C

TYPES OF CHILLING TECHNIQUES

- Air Blast Freezer: The product is surrounded by refrigerated gas (-30°C to -40°C)

- Plate Freezer: The product has direct contact with the refrigerated metal plate (-30°C to -40°C)

- Deep Freezer: Small-scale fisheries investors use the deep freezer as a freezing equipment and for long term storage of frozen catfish (-4°C to -12°C)

8. PACKAGING/LABELLING

After cooling, the catfish cans are then labelled with manufacturer’s brand name which should also contain vital information like ingredients, nutritional breakdown, expiry date, food license or registration number etc.

9. STORAGE

On completion of the catfish canning process, the cans are then stored in cool and dry environment

10. MARKETING

Sales activities and logistics for moving them to sales distribution centers like shops and supermarkets are done here. This allows the consumers to be able to purchase the canned catfish products.

Share This Article: