Poultry Processing

August 3, 2025, 10:12 am

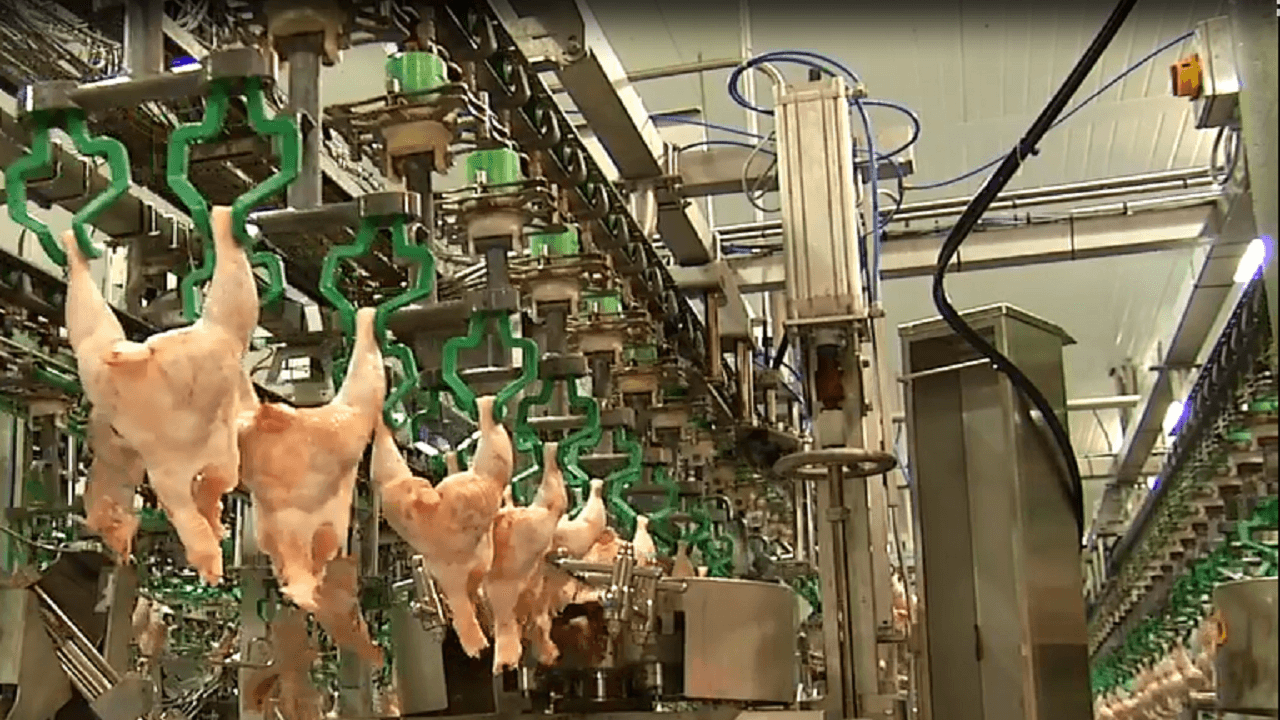

Ever since I visited the offices of Meyn Poultry Processing Solutions, I’ve been fascinated with the poultry processing industry.

I was shown around their production facilities by a senior executive,who also took his time to explain all the different components and aspects of the industry to me. In this post, I would like to share my knowledge about this very interesting and very profitable aspect of the poultry farming industry with you.

What is Poultry Processing?

Poultry processing is the conversion of live poultry into raw and packed poultry products for human consumption through the use of advanced equipment systems and services.

Benefits of Poultry Processing

There are 3 major benefits of poultry processing:

-

It ensures that poultry meat is produced safely and with the highest quality

-

It ensures that poultry livestock (chicken, turkey, ducks etc.) are handled in an ethical and responsible way when they are being slaughtered

-

It also creates jobs through the value creation of poultry parts and by-products

Poultry Processing System

The equipment and devices which make it possible to process poultry vary in composition and the functions which they perform. They are modular in construction meaning that practically all components of the production process can be scaled up and you will not need to replace all modules when extending your capacity.

Intelligent management and production software are also incorporated to asses and monitor the various quality aspects of the poultry processing system. This software lets you monitor the technical condition of the equipment, the yield and performance of modules and the complete traceability of all your product flow.

The flow diagram below outlines the entire poultry processing process:

-

Live Bird Handling

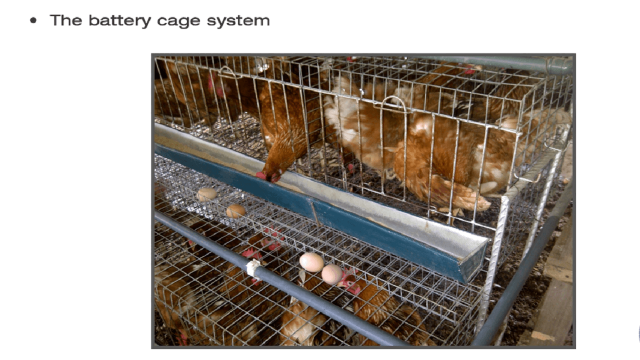

This system provides effective and animal-welfare friendly conditions for loading and transporting birds from the point where they are grown to the processing facility. The birds are usually transported by crates which can also be mechanical by using stackers and de-stackers.

-

Stunning

This is the system used to make the birds unconscious by an impact mechanism. The system ensures that blood spots and bone fractures hardly ever occur

-

Killing

An accurate and consistently executed kill cut is a vital step in poultry processing. The kill cut must ensure that the birds bleed out fully before they enter the scalding system

-

Scalding

This is where the dead birds are doused with boiling liquid or steam to make it easy to remove their feathers. The scalding process largely determines the appearance, colour and visual quality of the end product

-

Defeathering

This is where the feathers are removed from the birds by a plucking action. The plucking action will also determine the extent to which the skin remains attached to the poultry product. This is very important if the birds or portions from them are to be sold fresh

-

Evisceration

This is the system that removes the internal organs of the birds. This process can be done manually or automatically

-

Giblet Processing

Giblets are the heart and liver of the birds. They are usually removed from the birds before they are cooked. Giblets are popular and a profitable part of poultry processing. After harvesting, giblets must be washed, chilled and transported

-

Feet Processing

Poultry feet and paw are also very popular! Feet processing system is where the feet and paws are extracted and treated. It is a very interesting option to have for poultry processors

-

Chilling and Maturation

For optimum shelf life, quality, freshness and food safety, poultry products must be effectively chilled. It is important to chill the birds to correct breast core temperature without freezing wings or neck flaps. Good chilling ensures that customers are presented with an end product that has an attractive texture and colour

-

Weighing, Grading and Distribution

The weight and quality of both whole products and parts can be determined automatically at various points in the process. This is done using weighing equipment and vision technology. Automatic weighing, grading and distribution are important steps towards good in-plant logistics, full traceability, reduce give-away and improve yield

-

Cut-up

This is where the birds are cut into different parts. The system includes a full selection of wing, breast and leg processing modules

-

Deboning

This is the system that removes the bones from the poultry parts. The deboning system ensure high yield, top quality and safe end products

-

Batching

This system is responsible for packing the poultry parts. Batching systems can be fully integrated tray loading and packing systems that can pack up to 300 chicken fillets per minute into trays

-

Portioning and Slicing

This system offers additional cut-up of the poultry product. It delivers horizontal and template slicing of poultry fillet to ensure uniform and natural-looking end products

-

Meat Harvesting

This system ensures the possibility of harvesting any remaining valuable poultry meat from carcasses or necks. Mechanically deboned meat provides a profitable source of good quality raw material for the sausage, snack and comminuted meat industry

-

Marinating and Tumbling

The market for seasoned, ready-to-cook and ready-to-eat products continues to grow. Marinating and garnishing all kinds of bone-in and deboned products is very popular. This system adds value to poultry product and offers interesting possibilities in virtually all markets, with new tastes and applications being introduced all the time

-

Further Processing

This system offers full line solutions from meat preparation, portioning and coating to frying and cooking and even sausage production

-

Internal Logistics

This system improves the flow of the poultry products, safe guarding quality in the various process steps through the use of various types of conveyor belts and overhead conveyor systems for connecting process steps in the most efficient way possible

-

Packaging and End-of-line

End-of-line systems perform the final operations to complete the packing process and provide customer specified presentation

-

Cooling and Freezing

This system is for preserving the poultry products. Fast and efficient freezing are the keys to superior food preservation

-

Rendering and Waste Water Treatment

This system ensures that blood, feather, and other slaughter offal are transported and collected rapidly, effectively and hygienically. It also provides solution for the treatment and purification of waste water generated in the entire processing system so that it can be re-used and reduce damages to the environment

-

Data Acquisition and Logistics Control

Complex, high capacity processing requires ever more production control and management information. This system ensures that the entire plant processes are monitored and controlled for quality, control and maintenance purposes.

If you would like to see how all these different systems combine to make it possible to process poultry and convert them into packed products, then you need to watch our poultry processing video tutorials. To get access to our poultry processing video tutorials, click here to signup for our Poultry Processing video course

P.S. If you are interested in the poultry processing business and you need a poultry processing business plan to help you get started, we can help you. We help farmers and entrepreneurs prepare agribusiness plans for a fee and we have a poultry processing business plan you can get from us for a payment of N50,000. To learn more about how to get this plan, call/chat with us on +2348089864121 or send a mail to agsolutions@agricdemy.com

Share This Article: