Corona Virus Agribusiness Value Chain Innovations

October 27, 2020, 12:36 pm

As we are about to enter into the last quarter of 2020, which signals the beginning of winter in the polar and temperate climates of the world, health experts are predicting the second wave of the corona virus pandemic.

Corona Virus Agribusiness Value Chain Innovations

The corona virus belongs to the family of flu viruses which tends to infect more people when the weather is colder.

In fact, corona virus cases are already increasing in countries like United Kingdom, United States, India, France, Canada etc.

As more corona virus cases are recorded all over the world, there will be another lock down and restriction of movement of people and goods.

I think this is a good time to reflect on the issues or lessons learned from the last lock down, especially as it relates to agribusiness.

The common or biggest agribusiness issue from the last lock down was Wastage. Farmers lost a lot of produce when the lock down was effected.

There were two reasons for this. The first is the very long distance between farmers and consumers.

Because most farms are located very far from where the consumers are, when the lock down was effected, consumers (retail and wholesalers) couldn’t get to the farms to buy produce. As these produce couldn’t be sold on time, they got spoiled. This resulted in a lot of losses for many farmers.

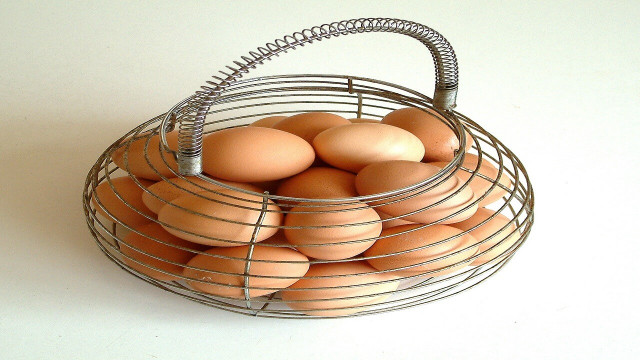

For example, I know a poultry farm in Ogun state where over 5,000 crates of eggs were lost because of this.

The second reason for wastage is that most farmers keep their produce in highly perishable form which, if not sold on time, gets spoiled quickly.

This agribusiness wastage situation made more pronounced by the corona virus lock down is begging for solutions or innovations to the agribusiness value chain.

Two solutions to this issue immediately comes to mind and they are:

- Growing or producing closer to the market

- Processing of farm produce

Growing closer to market

This is the ideal solution for all agriculture businesses because it makes it easier for your consumers to reach you regardless of any social or transport restrictions put in place. This is especially important for farmers who produce highly perishable produce like vegetables and fruits. When the first lock down was effected, fruits and vegetable farmers experienced a lot of losses because their produce couldn’t get to consumers on time.

Being near to the market, reduces wastage because produce can be sold as soon as they are harvested and farmers won’t suffer losses from rottenness.

Greenhouse farming makes this a reality for vegetable and fruit farmers because they can setup their vegetable and fruit farms very close or inside neighborhoods and residential areas such that consumers can stroll to their farms to buy vegetables and fruits like tomato, pepper, cucumber, melon etc.

Producing near the market will be harder for animal farmers because of the odor produced from the animal excrement. However, with a good feeding plan (quality ingredients used in producing feed, proper diet etc.) and good health management system (multivitamins, vaccinations etc.) odor from animal excrement can be drastically reduced. When this is coupled with frequent waste disposal, animal farmers can also setup shop very close to residential areas too and be closer to their consumers.

Produce processing

One of the advantage of processing is elongating the life span of farm produce. Processing takes a highly perishable farm produce and converts it into a non-highly perishable form. For example, raw cassava tubers can last for about one month but if the same cassava tubers are converted into gari, it will last for one year!

So, if you are able to process your farm produce, the issue of wastage is eliminated. Processing is even possible for farm produce like eggs too. They can be converted into powder form which can last over 3 months without been eaten. This isn’t possible with the raw eggs which have to be consumed in less than 2 weeks or they will get spoiled.

Processing must be the long-term aim of all farming businesses because apart from reducing losses from wastage, processed products command higher prices in the market. Crop farmers should pursue this aggressively.

During the lock down, most crop farmers who couldn’t process their crops just left them in the soil, they didn’t harvest the crops. This is a good way of elongating the crop life when you don’t have buyers or you can’t sell. As long as the crops remain in the soil, they won’t rot. But leaving them in the soil exposes them to damage from pests and animals so this isn’t a viable long term solution if another lock down is implemented.

I think the need for processing, especially crop processing, has been made more prominent by the corona virus lock down. While there are many crops crying out for processing, I believe the one crop that if processed as the most strategic benefit is cassava.

Let me explain.

Nigeria is an import-dependent economy with over 200 million people. The food requirement of Nigeria’s population is being met by companies like Dangote, Flour Mills, Honey well etc. who produce a lot of the staple foods that Nigerians consume. And many of the raw materials they use in producing our food are imported.

According to the National Bureau of Statistics, Nigeria imports agricultural products valued at over N230 billion every quarter. The major agriculture product that is imported into Nigeria is wheat. Wheat is imported mainly from the United States and Russia.

What do the companies that import wheat do with this wheat?

One of the major thing they use wheat for is producing is pasta (spaghetti) and noodles.

Nigerian pasta consumption is growing, accounting for about 15% of wheat flour usage, up from virtually zero in 1999. Flour Mills of Nigeria pioneered pasta production in 1999; since then it expanded pasta production capacity from 40,000 MT (1999) to 350,000 MT today. Dangote similarly expanded its own milling capacity from 15,000 MT/year in 2000 to a total installed capacity of 800 MT/day currently. Other major players in pasta production include Honeywell, Flour Mill and OLAM/Crown Flour Mills. Expansion began in earnest in 2003 following the government imposing a 100% tariff on imported pasta and biscuits.

When corona virus infection rates rises again, it will cause another economic slowdown which will lead to drop in oil prices and reduction of dollar earnings for Nigeria. A drop in dollar earnings for Nigeria, leads to dollar shortages for importers. Due to the shortage of dollars, there’s going to be a rise in the cost of importing wheat into Nigeria and this will cause an increase in the price of products produced from wheat e.g. spaghetti, noodles, bread etc.

Cassava can replace wheat in the production of products like spaghetti and noodles. Cassava has many properties similar to wheat and it grows better in Nigeria than wheat does.

Cassava is one of the most important crops in Nigeria. It is the most widely cultivated crop in the southern part of Nigeria in terms of area devoted to it and number of farmers growing it. Indeed, it is grown by almost every household.

Cassava is a very versatile crop. Its root starch can also be used in a wide array of industries, including food manufacturing, pharmaceuticals, textiles, plywood, paper and adhesives, and as feed stock for the production of ethanol bio fuel. Cassava flour can also be used in the production of bread, snacks, pasta, noodles, biscuits and other confectioneries which Nigerians love.

Presently, the food producers (bread, snacks, pasta, and instant noodles) in Nigeria spend over $4billion per year importing wheat flour to produce their goods. For years, the Nigerian government has been actively pursuing a policy to reduce wheat imports by 50% over the next year and is requiring flour millers to include 10% of cassava flour in their bread flour, with the goal to ultimately include 40% in the coming years.

With the global economic problems caused by corona virus, the time for food producers to switch from wheat to cassava has finally arrived!

This is a big opportunity for cassava farmers and processors to take advantage of.

If you would like to know more about cassava processing, then check out our cassava processing video training and if you want to have a better understanding of the cassava processing business, then you can get our cassava processing business plans.

Share This Article: